Some optional equipment shown.

Some optional equipment shown.

The Pick Sanitary Steam Injector is the preferred choice for in-line product cooking, CIP heating or nitrogen gas injection.

The Pick SC heats or cooks any water-miscible liquid or slurry instantly on a continuous straight through basis. It can handle slurries containing bite sized particulate such as salsas or stews…with particulate integrity retained!

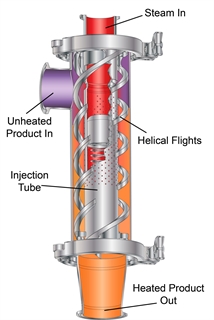

The Pick Sanitary Heater/Jet Cooker achieves set point temperature instantly and provides a thorough cook of products like starches using its unique, low velocity, variable orifice steam injector and helical flights to ensure intimate and gentle blending of steam and product without high shear and product degradation commonly found with sonic velocity venturi systems. Forget the inherent process inefficiencies and maintenance headaches of traditional batch cooking.

The Pick Sanitary Heater meets 3-A sanitary requirements for regulatory compliance with food and dairy applications. Pick Direct Steam Injection allows you to heat in-line, with precise temperature control and 100% energy efficiency.

3A Certified

Pick Sanitary Heaters/Jet Cookers carry the 3A symbol. The 3A symbol certifies the heater is in regulatory compliance for any food or dairy application. All product surfaces are 316L Stainless Steel with #4 (32 Ra) sanitary polish. Tri-clamp® connections are standard, and other connections are available upon request. The entire unit disassembles in minutes for routine inspection and cleaning.

Application Data Forms & Brochure Downloads

Need a quote for a Pick Steam Injection Heater? Save time by submitting an application data sheet. Just looking for additional information on our products? Download our product specific brochures.

Submit Sanitary Application Data Sheet

Download Pick Sanitary Heater/Jet Cooker Brochure

Need a Replacement Part or Manual?

Request Replacement Parts

Contact us to order the parts you need to keep your Pick Heater up and running.

Request a Manual

Contact us to request a copy of the Service and Installation Manual for your Pick Heater.

Read a Related Blog Post or Article

The Benefits of Continuous Cooking with Direct Steam Injection Heaters vs. Traditional Batch Cooking

Advantages of Direct Steam Injection to Process Pet Foods

Pick Assists Start-up Candy Company

Customer Finds Success with Pick Direct Steam Injection

Typical Applications Include:

Typical Pharmaceutical Applications Include:

Have a Question or Need More Information?

We’re committed to providing the best customer support before and after the sale with a team of factory sales engineers that are recognized experts in the industry. They’re ready to put that expertise to work for you.

In-Line Cooking

Pick Sanitary Heaters eliminate slow batch processing. Heat, cook or sterilize on a continuous, straight-through basis. The Pick Direct Steam Injection heater processes higher volumes of quality product in less time than any other heating method.

Non-Shearing Action

Helical flights inside the heater body allow a generous, unobstructed flow path for liquids and slurries. Because the Direct Steam Injection process is non-shearing, slurries containing bite-sized particulate can be heated without damage to texture or consistency. Product integrity is maintained, cooking is thorough and fast, and blending is uniform.

Precise Temperature Control

Pick's precise temperature control assures exceptional product quality. With Pick Sanitary Direct Steam Injection, quality control problems common to jacketed kettle cooking or sparging are virtually eliminated. In addition, a separate steam control valve eliminates stem packing leakage (common with close coupled units) and possible product contamination.

Easy Installation and Maintenance

The Pick Sanitary Direct Steam Injection unit can be delivered to you complete and ready to install. Simply connect the system to your steam and product piping and start heating. In comparison to competitive methods, the Pick Heater requires very little effort to clean and maintain. The unit can be easily disassembled in minutes for routine inspection and COP cleaning. Nothing could be simpler, or faster to maintain.

The Pick Heater is an engineered product and heater selection is primarily based on Steam Demand.

For preliminary heater selection use the following Sizing Formula. Next match the liquid flow rate to the appropriate pipe size. The selection should be verified by your local Pick Heater Rep or a Factory Sales Engineer.

Please contact us with questions.

Sizing Formula:

Steam Demand (lbs/hr)

Product (lb/hr) X ∆ T (ºF) X Specific Heat / 1,160

Steam Demand (kg/hr)

Product (kg/hr) X ∆ T (ºC) X Specific Heat / 650

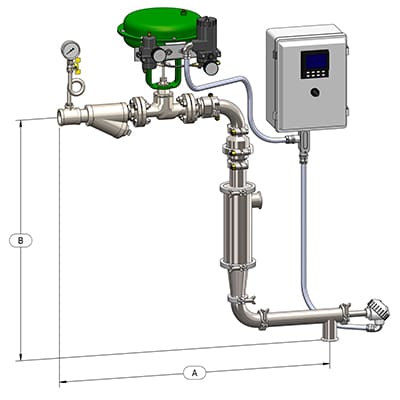

Drawing of Sanitary Jet Cooker System

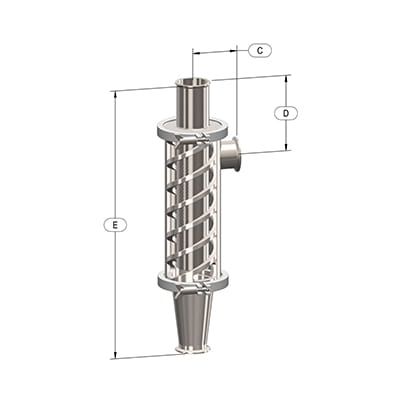

Drawing of Sanitary Jet Cooker Unit Only

Sanitary Heater/Jet Cooker Technical Specifications

| Model No. | SC2 | SC7 | SC10 | SC25 | SC50 | SC75 | SC100 | |||||||||||||||||||||||||||||||||||||||||

| Steam Capacity |

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||

| Product Ports (inches) | 0.5 - 1.5 | 1 - 2 | 1 - 2.5 | 1.5 - 3 | 2 - 4 | 3 - 6 | 3 - 6 | |||||||||||||||||||||||||||||||||||||||||

| Steam Ports (inches) | 1 | 1 | 1.5 | 2 | 2 | 4 | 4 | |||||||||||||||||||||||||||||||||||||||||

| Approximate Dimensions (inches) |

|

|

|

|

|

|

|

|

Standard steam inlet assembly consists of a strainer, control valve, sanitary check valve, and associated fittings. Optional separator and filter are available for culinary steam service.

Custom Systems

Pick Pre-Packaged Hot Water sets are custom designed to meet process industry needs effectively and efficiently.