A Pick BX Heater provides instantaneous and complete cooking of starch and other water-miscible slurries. It is also a great choice for viscous slurries such as waste grease and oil. Heating with a Pick BX efficiently reduces the viscosity to promote separation of components at the centrifuge.

It is proven effective on pearl, modified, and cationic starches with solids concentrations up to 35% and cooking temperatures ranging from 90°C – 150°C.

The low velocity design minimizes mechanical shear of the starch granules... an important consideration for cooking most cationic starches.

These heaters can also perform "double duty." They are often used to pre-heat water which is then blended with the starch powder to form the initial slurry. The slurry is then pumped back through the same heater for final cooking.

These compact, non-plugging BX Direct Steam Injection Heaters are available to process flow rates in excess of 600 GPM.

Application Data Forms & Brochure Downloads

Need a quote for a Pick Steam Injection Heater? Save time by submitting an application data sheet. Just looking for additional information on our products? Download our product specific brochures.

Download Slurry Heater Brochure

Download Pick Steam Injection Heater Brochure

Need a Replacement Part or Manual?

Request Replacement Parts

Contact us to order the parts you need to keep your Pick Heater up and running.

Request a Manual

Contact us to request a copy of the Service and Installation Manual for your Pick Heater.

Read a Related Blog Post or Article

Benefits of Direct Steam Injection for Starch Cooking

Improve Your Waste Grease Recycling Process with Direct Steam Injection

Benefits of Industrial Wastewater Treatment Using Direct Steam Injection

Why Direct Steam Injection Liquid Heating is the Preferred Choice for Many Industrial Applications

Typical Applications Include:

Have a Question or Need More Information?

We’re committed to providing the best customer support before and after the sale with a team of factory sales engineers that are recognized experts in the industry. They’re ready to put that expertise to work for you.

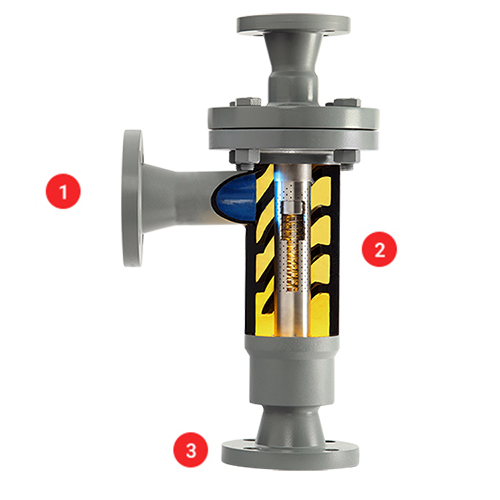

The unique design of the Pick BX Heater offers key advantages over other high-velocity venturi devices and indirect heat exchangers.

Low Pressure Drop

Starch flows through the heater without obstruction. This results in negligible pressure drop when handling high viscosity formulations.

Low Noise

Noise generation is significantly lower and pipe vibration virtually eliminated.

Non-Shearing

Non-shearing action provides uniform product consistency

Low Velocity Mixing

This provides a “thorough cook” of starch granules yielding a better cooked product.

The Pick Heater is an engineered product and heater selection is primarily based on Steam Demand.

For preliminary heater selection use the following Sizing Formula. Next match the liquid flow rate to the appropriate pipe size. The selection should be verified by your local Pick Heater Rep or a Factory Sales Engineer.

Please contact us with questions.

Sizing Formula:

Steam Demand

(lb/hr)= 0.43 x flow(GPM) x ∆ T (ºF)

or

(kg/hr) = 0.092 x flow(LPM) x ∆ T (ºC)

Example: 200 GPM x 50ºF temperature rise x 0.43 = 4,300 lb/hr of steam. You would require a 6X50-3BX which has a maximum rated steam capacity of 5,000 lb/hr, and a maximum water flow rate of 500 GPM with welded flanged connections.

Steam Injection Constant Flow Starch Cooker

BX Slurry Heater Technical Specifications

| Model No. | 6X7-1BX | 6X10-1BX | 6X25-1BX | 6X50-1BX | 6X75-1BX | 6X100-1BX | 6X150-1BX | 6X200-1BX | 6X350-1BX | 6X500-1BX | ||||||||||

| Steam Capacity | Lb/hr | 700 | 1,250 | 2,500 | 5,000 | 7,500 | 10,000 | 15,000 | 20,000 | 35,000 | 50,000 | |||||||||

| Kg/hr | 320 | 565 | 1,130 | 2,260 | 3,390 | 4,520 | 6,780 | 9,040 | 15,820 | 22,600 | ||||||||||

| Liquid Pipe Size Range (inches). | Flanged | ¾ - 2 | 1 - 3 | 1 ½ - 4 | 2 - 4 | 2 - 6 | 2 ½ - 6 | 3 - 8 | 4- 10 | 4 - 10 | 6 - 12 | |||||||||

Heaters are manufactured in Carbon Steel or 316SS. Other alloys/materials available upon request. Liquid and steam piping is available in ANSI/DN Flanged construction.

Custom Systems

Pick Pre-Packaged Hot Water sets are custom designed to meet process industry needs effectively and efficiently.