Application:

A converting mill producing a range of specialty coated printing and copier papers, required a steam injection heater for cooking cationic starch slurry, up to 35% solids. The heater serves a dual function. First, water is pre-heated to 140°F and blended with starch powder. Then the starch slurry is pumped back through the heater at a rate of 40 GPM and cooked at 200°F. Depending on the recipe, post dilution is used to obtain final consistency.

Process Conditions:

Slurry and Water Flow Rate: 40 GPM

Inlet Temperature: 50°F

Final Cook Temperature: 200°F

Steam Pressure: 65 PSIG

Water Pressure: 50 PSIG

Required Steam Flow: 2,580 lb/hr

Solution:

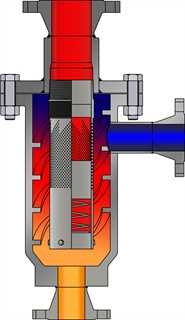

A Pick Model 6X25-3BX Heater was selected for this application. Its generous flow-through design imposes negligible pressure drop on the slurry. It provides thorough cooking at a precisely controlled temperature. The low velocity design minimizes mechanical shear of the starch granules, an important factor for most cationic starches.

Features and Benefits:

• Low Pressure Drop

• Precise Temperature Control

• Low Mechanical Shear

• Compact Design

• Non-Plugging