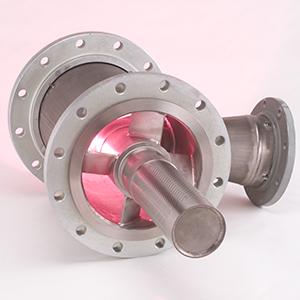

Same trusted features and benefits of standard models, but for flow rates, pressures or material of construction that are outside the standard design.

In fact, flow rates of up to 25,000 GPM (5680 m3/Hr.) are available.

High pressure designs (ANSI Class 900 PSIG, or DN 900 / PN 260) and above. Specialty heaters can also be made in special alloys such as…AL-6XN, Hastelloy, Duplex 2205, Titanium, Inconel etc.

Please contact Pick Heaters or fill out our application data sheet for a quote on a Pick Specialty DSI Heater.

Application Data Forms & Brochure Downloads

Need a quote for a Pick Steam Injection Heater? Save time by submitting an application data sheet. Just looking for additional information on our products? Download our product specific brochure.

Need a Replacement Part or Manual?

Request Replacement Parts

Contact us to order the parts you need to keep your Pick Heater up and running.

Request a Manual

Contact us to request a copy of the Service and Installation Manual for your Pick Heater.

Read a Related Blog Post or Article

Why Direct Steam Injection Liquid Heating is the Preferred Choice for Many Industrial Applications

How to Calculate Your Steam Needs

Saving Money, Improving Efficiency with Direct Steam Injection

Typical Applications Include:

Have a Question or Need More Information?

We’re committed to providing the best customer support before and after the sale with a team of factory sales engineers that are recognized experts in the industry. They’re ready to put that expertise to work for you.

Low Liquid Pressure Drop

Pressure drop is less than 2 PSI

Complete Mixing Inside Heater Chamber

No up or down stream straight pipe length requirements

Low Sound Level

Typically less than 85 dBA

Compact Design

Compared to indirect heat exchangers

Steam injection flow rates up to 50,000 lb./hr. (22,680 kg/hr.). Straight in-line pipe and 90° Elbow designs available.