How Pick Direct Steam Injection Heaters Work. Simple, Durable, Dependable Design.

Quiet-Efficient-Reliable

Pick Direct Steam Injection Heating Systems can be used to heat any water-miscible liquid or aqueous slurry instantaneously where 30 PSI (2.1 BAR) or above steam pressure is available.

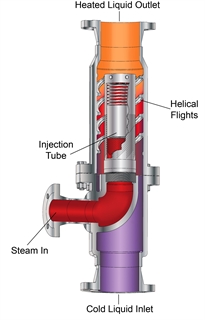

The Pick System injects steam into the liquid through hundreds of precisely arranged orifices in the injection tube. Steam is thoroughly mixed and absorbed by the liquid in the heater chamber. Therefore, there are no minimum straight piping requirements before or after the Pick Heater.

Our method of injection sets Pick apart from all other Direct Steam Heaters.

The steam injection tube and spring-loaded piston form the heart of the Pick Heater, which serves three critical functions:

With its simple design, minimal moving parts, exceptional temperature control, energy efficiency, low liquid pressure drop, and compact design Pick Direct Steam Injection (DSI) Systems regularly outperform heat exchangers and high velocity steam eductors.

For more information - contact us.