Say goodbye to slow, uneven cooking—and hello to faster, cleaner, more efficient food processing.

If your cooking process is still relying on traditional batch cooking methods, it may be time to rethink what’s possible. With a Pick Sanitary Heater/Jet Cooker, food and beverage manufacturers can unlock the power of continuous cooking using direct steam injection, an innovative approach that delivers rapid, uniform heating, reduces energy costs, and streamlines maintenance. In this blog post, we’ll break down the key differences between batch and continuous cooking and explain why upgrading to a Pick Sanitary Heater could be the smartest investment you make this year.

Batch Cooking: Tried and True - but Not Without Limitations

Traditional batch cooking involves processing a fixed amount of product in a vessel, heating it to the desired temperature, and then cooling or transferring it before starting the next batch. This method is commonly used for smaller production runs or products that require specific batch recipes.

- Heating Method: Heat is typically applied through jacketed kettles or heat exchangers, which can result in uneven heating and longer processing times as heat needs to transfer across the jacket or plate surface.

- Temperature Control: Temperature control in batch cooking is less precise or responsive, as it relies on external heating sources and the thermal conductivity of the vessel and product.

- Energy Efficiency: Batch cooking methods often have lower heat transfer efficiency, resulting in higher energy usage and costs.

- Maintenance: The problem of fouling results in the need to clean and maintain large vessels and heat exchangers can lead to increased downtime and maintenance costs.

Advantages:

- Flexibility: Batch cooking can be advantageous for small-scale production or products that require specific batch processing.

- Control: Allows precise control over individual batches, which can be beneficial for certain recipes or formulations.

Continuous Cooking with Direct Steam Injection

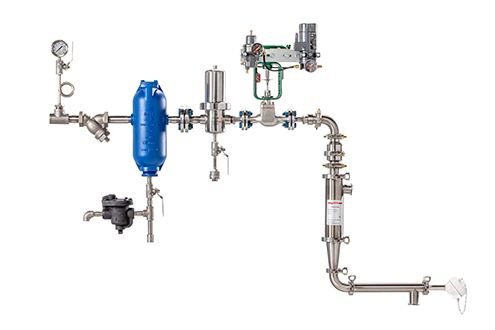

Unlike batch cooking, continuous cooking with a DSI Heater/Jet Cooker injects steam directly into the product stream—resulting in immediate and uniform heating without high shear or fouling. This method is designed for high-throughput processes that demand consistency and efficiency.

- Steam Injection: Steam is injected through a variable orifice steam injector, which ensures intimate and gentle blending of steam and product without high shear. This method achieves set point temperature instantly and provides thorough cooking.

- Temperature Control: The system offers precise and instantaneous temperature control, maintaining temperature within a narrow range to ensure consistent product quality.

- Energy Efficiency: Direct steam injection heaters achieve up to 100% heat transfer efficiency, as all the energy from the steam is used for heating.

- Maintenance: The units are designed for easy disassembly and cleaning, minimizing downtime and maintenance costs.

- No Condensate Return: With DSI, the regular maintenance and issues related to condensate traps and return lines is eliminated.

Advantages:

- High Throughput: Continuous cooking allows for a seamless, uninterrupted flow of product, resulting in higher throughput and reduced downtime.

- Uniform Heating: The direct injection of steam ensures uniform heating, eliminating hot spots and maintaining product integrity.

- Energy Savings: The high heat transfer efficiency reduces energy consumption and operational costs.

- Reduced Maintenance: The robust design minimizes the risk of fouling and scaling, leading to lower maintenance requirements.

Experience the Pick Advantage

Whether you're scaling up or simply looking to modernize your cooking process, the Pick Sanitary Heater/Cooker offers a proven solution that outperforms traditional methods in virtually every category. With over 80 years of expertise, Pick Heaters, Inc. helps processors across the food, dairy, and beverage industries cook smarter, faster, and cleaner.

Ready to elevate your situation? Consider the benefits of in-line direct steam injection processing. Contact us to discover how a Pick Heater can transform your production line today.