American pet owners spend an estimated 103.6 billion dollars for their furry friends, in which 42.0 billion is spent on pet food & treats and another 674.6 million is spent on vitamins and supplements. Producers of food products are looking for ways to capture some of this market and maximize their production equipment while still ensuring the end product is a quality item that meets specific parameters.

One effective method to consider for processing heated pet food products or supplements is through the use of the Direct Steam Injection (DSI) System. Whether you are looking to expand into the market and create an entire new production line, maximize the production of an existing line, or want to ensure the quality of the finished product, the DSI system might be the answer to your production needs.

- Size and cost; unlike the myriad of indirect heat exchange systems or large batching kettles, a DSI system takes up very little space and is typically less costly. Consider first that an indirect system only utilizes the sensible heat (BTUs) from steam, instead of the benefit of using all the available heat (both latent and sensible BTUs) realized with DSI units. For the same duty the indirect units require more steam and more surface area to heat the same heat load as a DSI unit would. In other words, more surface area requires more cost to buy more stainless steel plates, tubes, tanks – that is all added cost.

Jones & Larner (1968) noted that the heat transfer coefficient of a DSI system was 600 times greater than that of an indirect system, in other words smaller is better for heating and more cost effective. Additionally, indirect steam heated units require condensate return lines, so again more added costs.

- Because the steam is directly injected into a liquid or slurry with a DSI unit, there is a faster rise in temperature through a smaller device that has less surface area. The result is less browning, and minimal heat degradation of proteins compared to the more widely known indirect heat exchanger methods.

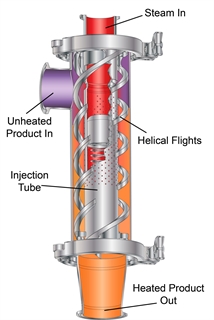

Cutaway View of Pick Sanitary Direct Steam Injection (DSI) Cooker

- With DSI the pet food/supplement producer has the ability to process items at much higher temperatures while not worrying about product fouling. With indirect heating methods and their need for greater surface areas, there is a higher probability for product filming, burning on, and greater likelihood for denaturation of proteins. Using a DSI system with its smaller surface area generally eliminates or greatly reduces the level of denaturation.

- For products that require encapsulation or gelatin binders to hold all the supplements together, using a DSI system is an effective low-cost de-aerator. When gelatin is incorporated into slurries as a binder, the gelatin material becomes the world’s greatest air attractor. The slurry tends to take on a frothy almost marshmallow-like appearance, and unless the producer wants to slow down agitator speeds or use expensive de-gassing methods like a vacuum chamber to remove air bubbles, the DSI system may be the answer. After instantly heating the slurry to a temperature above 212°F (100°C), the slurry will pass across a back pressure valve which is used to keep the slurry under pressure. After the back pressure valve, the slurry will fall in pressure and all the excess steam (steam used to heat a product above 212°F) will flash off along with the air in a stripping method. What stays behind is a near bubble free liquid ready for depositing, casting, or further processing into the final form.

In conclusion, the DSI system can offer you space savings (they tend to be much smaller), cost savings (far less expensive compared to larger batch kettles or other indirect systems), less protein denaturation, more energy efficient, and an effective alternative to clarity issues typically experienced with gelatin related products.

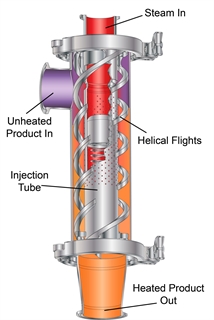

Sanitary SC-3 Direct Steam Injection System with optional separator and stainless steel filter

To learn more, contact us.