Application:

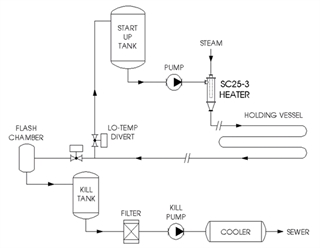

Large pharmaceutical facility wanted to convert their batch processing method for bio-waste treatment to a continuous flow system. Temperature of 130ºC had to be reached and held for 5 minutes to effectively “kill” and neutralize living cells. The waste stream is then cooled prior to discharge to sewer. A 304L stainless steel shell and tube heat exchanger was also considered. Waste treatment time would be significantly reduced from the normal 30-45 minute batch.

Process Conditions:

Temperature Rise: 70ºC

Discharge Temperature: 140ºC (285ºF)

Steam Supply Pressure: 100 PSIG

Liquid Supply Pressure: 53 PSIG

Steam Flow: 830-2,054 lbs/hr

Solution:

Pick SC25-3 Sanitary Heater with 1-1/2” tri-clamp liquid connections. Heater was installed prior to holding vessel and flash chamber.

The cast stainless steel Pick Heater can be used where sanitary finish and design are not required.

Features and Benefits:

• Accurate Temperature Control

• Easy Cleaning

• Instant Response to Heating Requirements

• Compact Design