The Pick Constant Flow Steam Injector is used wherever a relatively constant flow of heated liquid at a precisely controlled temperature is required.

The Constant Flow Steam Injector mixes medium-to-high pressure steam with cold water and delivers instant hot water. It is ideal when the water flow is fixed or varies over a narrow span (3:1).

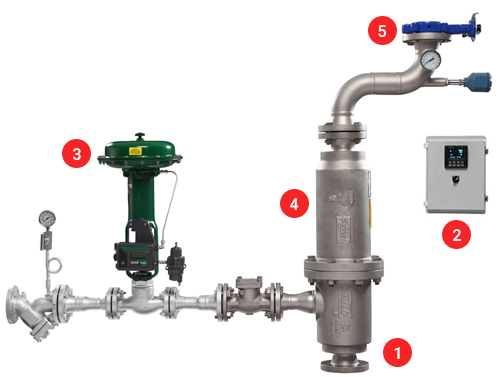

The Pick Heater is delivered as a complete, compact system and can be easily customized with additional controls, valves, and instrumentation to meet your plant specifications. Save space, energy and maintenance costs using a Pick Constant Flow Heating System.

For water flow turndown beyond 3:1 or rapid start-stop cycling applications, please refer to our Variable Flow design.

Application Data Forms & Brochure Downloads

Need a quote for a Pick Steam Injection Heater? Save time by submitting an application data sheet. Just looking for additional information on our products? Download our product specific brochures.

Need a Replacement Part or Manual?

Request Replacement Parts

Contact us to order the parts you need to keep your Pick Heater up and running.

Request a Manual

Contact us to request a copy of the Service and Installation Manual for your Pick Heater.

Read a Related Blog Post or Article

How to Calculate Your Steam Needs

Why Direct Steam Injection Liquid Heating is the Preferred Choice for Many Industrial Applications

Improve Jacketed Heating Systems with Direct Steam Injection

Typical Applications Include:

Have a Question or Need More Information?

We’re committed to providing the best customer support before and after the sale with a team of factory sales engineers that are recognized experts in the industry. They’re ready to put that expertise to work for you.

No Steam Hammer

Eliminates harmful vibration and steam hammer which can lead to product and equipment damage.

Exceptional Temperature Control

Precise, accurate temperature control +/- 1°C

Energy Efficient

100% heat transfer - cuts fuel costs as much as 28% compared with indirect heat exchangers

Low Liquid Pressure Drop

Pressure drop does not exceed 2 PSI (0.14 BAR) under design flow rates

The Pick Heater is an engineered product and heater selection is primarily based on Steam Demand.

For preliminary heater selection use the following Sizing Formula. Next match the liquid flow rate to the appropriate pipe size. The selection should be verified by your local Pick Heater Rep or a Factory Sales Engineer.

Please contact us with questions.

Sizing Formula:

Steam Demand

(lb/hr)= 0.43 x flow(GPM) x ∆ T (ºF)

or

(kg/hr) = 0.092 x flow(LPM) x ∆ T (ºC)

Example: 200 GPM x 50ºF temperature rise x 0.43 = 4,300 lb/hr of steam. You would require a 6X50-3 which has a maximum rated steam capacity of 5,000 lb/hr, and a maximum water flow rate of 230 GPM with threaded connections (500 GPM with welded flanged connections).

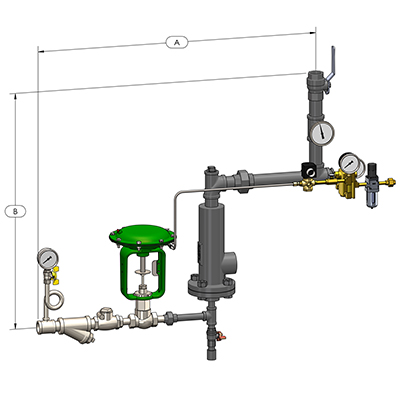

Drawing of 6X7-3 Constant Flow Direct Steam Injection Heater

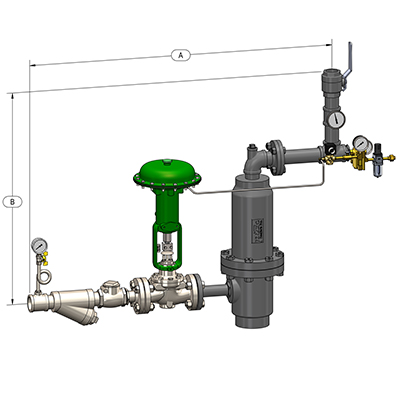

Drawing of 6X10-3 thru 6X500-3 Constant Flow Direct Steam Injection Heater

| Model No. |

6X7-3 |

6X10-3 |

6X25-3 |

6X50-3 |

6X75-3 |

6X100-3 |

6X150-3 |

6X200-3 |

6X350-3 |

6X500-3 |

|||||||||||||||||||||||

| Steam Capacity |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

Liquid Pipe Size Range (inches) |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

| Approximate Dimensions (inches) |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

| Shipping Weight (lbs) | 275 | 300 | 350 | 440 | 600 | 825 | 950 | 1,800 | 2,400 | 3,000 |

Liquid Pipe Selection Table

Choose best pipe size based on water flow rate in GPM

| Pipe Size | 1 | 1 - 0.25 | 1 - 0.5 | 2 | 2 - 0.5 | 3 | 4 | 6 | 8 | 10 |

| Max. GPM | 15 | 30 | 45 | 90 | 140 | 230 | 500 | 1000 | 1800 | 3000 |

Heaters are manufactured in Cast Iron, Carbon Steel, or 316SS. Other alloys/materials available upon request. Liquid and steam piping is available in NPT Threaded or ANSI/DN Flanged construction.

Custom Systems

Pick Pre-Packaged Hot Water sets are custom designed to meet process industry needs effectively and efficiently.