Application:

A regional power plant installed two new reverse osmosis (R/O) systems to reduce the amount of conventional chemical treatment for boiler feed water. The purpose of the R/O system was to demineralize and remove impurities in a filtered water supply via a series or bank of semi-permeable membranes. Water at cold temperatures reduces the efficiency of the R/O system, lessening the ability of water to pass through the membranes. A preheat system was specified to hold incoming water at 76ºF as inlet temperature dropped during the winter months.

Process Conditions:

Water Flow Rate per R/O System: 410 GPM

Maximum Water Flow Rate: 820 GPM

Inlet Temperature: 51ºF

Discharge Temperature: 76ºF

Steam Supply Pressure: 150 PSIG

Water Supply Pressure: 75 PSIG

Steam Flow Required: 4,410-8,820 lbs./hr.

Solution:

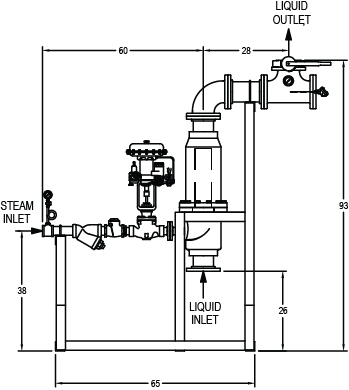

Pick Model 6X150-3/15 Constant Flow Heater- The constant flow design, in cast iron construction, was selected to handle the turndown requirement of the two systems. In comparison to indirect methods of heating, the Pick Heater is the most cost effective and simplest design. The inherent advantages of the Pick Heater came through in a successful startup. It has been in service since the winter of 1998.

Features and Benefits:

• Instant Supply of Tempered Water

• Improved R/O System Efficiency

• Accurate Temperature Control

• Simple Operation

• Compact Design