Application:

A seafood processor required hot water supply for aseptic pasteurization of artificial crab product. The product, sealed in plastic bags, passed through a three-stage belt pasteurizer. This is the first stage requiring hot water be held at 205ºF, heated by internal steam coils. The packets then go through two chilling sections before refrigeration and boxing.

A heating system was required to heat the cold make-up water supplied to the system as water is lost through evaporation, spills and carryover. Maintaining a minimum pasteurization temperature was critical to the process.

Process Conditions:

Water Flow Rate: 15 GPM

Inlet Temperature: 40ºF

Discharge Temperature: 205ºF

Steam Pressure: 60 PSIG

Liquid Pressure: 20 PSIG

Steam Flow Required: 1,065 lbs./hr.

Solution:

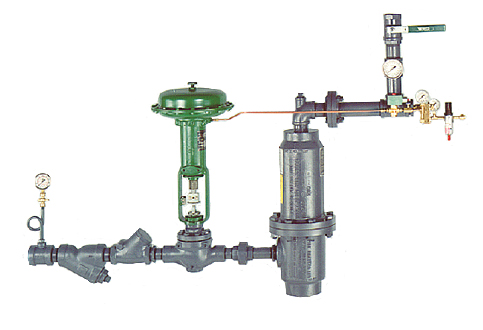

Pick Model 6X10-3 Constant Flow Heater, cast iron construction with threaded fittings. The Pick system provides accurate temperature control and quickly reaches set point as soon as make-up water is called for.

Features and Benefits:

• Precise Temperature Control

• Instantaneous Supply of Hot Water

• Ease of Installation on Existing System