Application:

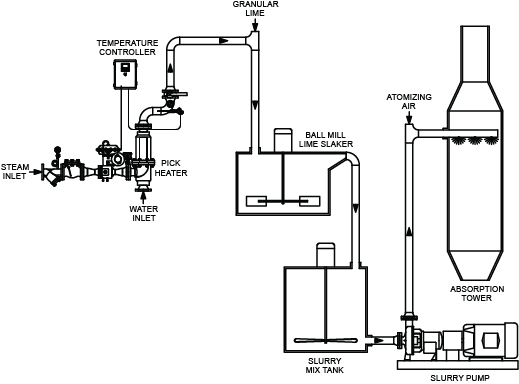

Environmental regulations require power plants to employ flue gas desulphurization (FGD) to control sulfur dioxide (SO2) emissions. Limestone scrubbing is the method of choice for coal-fired plants, yielding efficiencies of 90% - 98%. SO2 is neutralized by direct contact with limestone slurry in an absorption tower.

Slurry is produced by crushing limestone in a ball mill and mixing it with water. During this slaking process, conversion to calcium hydroxide is achieved. Surface area of calcium hydroxide particles is the critical factor for scrubber efficiency. Use of hot water at 110°F - 120°F supplements heat of reaction. This improves slaking efficiency and reduces lime consumption.

Process Conditions:

Water Flow Rate: 200 GPM

Discharge Water Temperature: 110°F

Temperature Rise: 40 - 60 °F

Solution:

Pick Model 6X50-3 Constant Flow Heater in carbon steel construction. The Pick Heater provides a simple, yet reliable source of hot water at precisely controlled temperature.

Features and Benefits:

• Improved Slaking Efficiency

• Reduced Lime Consumption

• Compact Size

• Precise Temperature Control