Application:

In the chemical pulping process, cooking liquor (spent liquor) that is separated from the washed stock goes through an evaporation process to form black liquor. The black liquor becomes fuel for the recover boiler. The resulting furnace smelt is dissolved to form green liquor. After a clarification process (removal of insoluble material,) the green liquor is fed into a lime slaker where it mixes and reacts with lime. White liquor is produced, which in turn is used in the pulp cooking process. The reaction in the slaker takes place at temperatures around 185- 195°F. Overheating of green liquor does not improve causticizing reaction efficiency and presents the risk of boil over.

Process Conditions:

Flow Rate: 503-647 GPM

Temperature Rise: 20°F

Discharge Temperature: 185°F

Steam Pressure: 150 PSIG

Green Liquor Pressure: 35 PSIG

Required Steam Flow: 4,323-5,564 lbs/hr

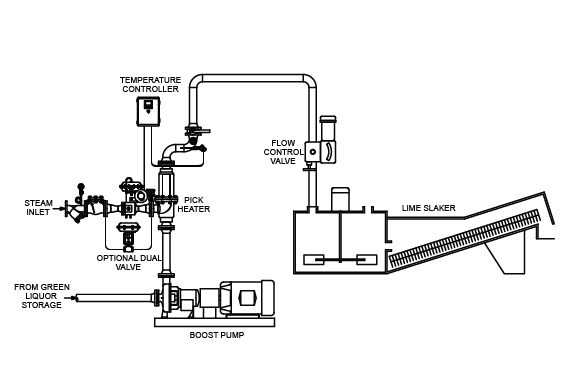

Solution:

The Pick Model 6X75-3 Constant Flow Heater was selected for added capacity. The Pick Heater can automatically adapt to changes of incoming liquor temperature. The heater was provided in 316L grade stainless steel to better handle caustic green liquor. The mill DCS controlled the discharge temperature of the heater.

Features and Benefits:

• Smooth, Quiet Performance

• Precise Temperature Control