Application:

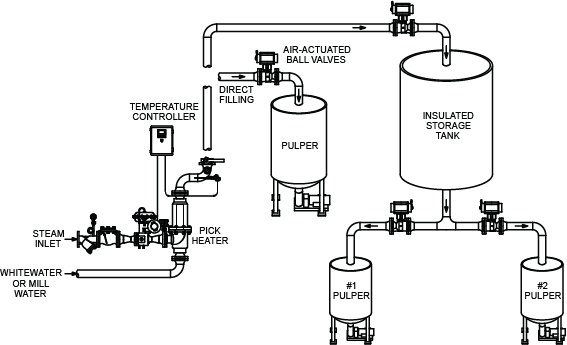

For recycled fiber, waste paper or secondary fiber is “re-pulped” in hydrapulpers to de-fiber into a 5-7% stock slurry. High temperature water added to the pulper serves to facilitate this mechanical de-fibering by increasing fluidity of the stock. Higher stock temperatures are also advantageous during the de-inking process, enhancing the efficiency of detergents and foaming agents used in this process.

Filling a hydrapulper with preheated water has important advantages over the commonly used steam sparging method. Hot water can be provided instantaneously at the demands of the process, bringing the system up quickly and reducing production time. Damage to the pulper caused by hammer during steam sparging is eliminated.

Process Conditions:

White Water Flow Rate: 200-300 GPM

Temperature Rise: 80ºF

Discharge Temperature: 180ºF

Steam Flow: 6,880-10,320 lbs./hr.

Solution:

Pick Model 6X100-3 Constant Flow Heater. The cyclic nature of this service makes the use of an instantaneous heater an obvious choice. The Pick Heater responds immediately as water is drawn into the pulper to bring discharge temperature up to setpoint within seconds. Start-up and shut down occur smoothly with no harmful noise and/or vibration.

Features and Benefits:

• Smooth, Quiet Operation

• Instantaneous Supply of Hot Water

• Low Liquid Pressure Drop