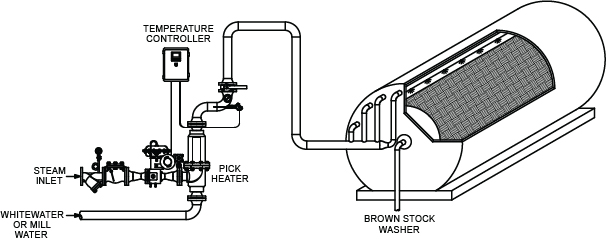

Application:

In the chemical pulping process cooked pulp, referred to as brown stock, discharges from the digester. Cooking liquors (spent liquor) is separated from the pulp for recovery. The use of a rotary vacuum washer is the typical method. Other forms of diffusion washing are also used. Wash water, sprayed onto the pulp stock through nozzles, is heated to around 180ºF to enhance the dispersal of cooking liquor.

Process Conditions:

Water Flow Rate: 500 GPM

Temperature Rise: 45ºF

Steam Pressure: 135 PSIG

Water Pressure: 45 PSIG

Steam Flow: 9,675 lbs./hr.

Solution:

Pick Model 6X100-3 Constant Flow Heater is an excellent choice for brown stock washer service. It can be dedicated to a single washer or used as a central supply for multiple units. It responds rapidly to variations in supply water flow rate or temperature to maintain precise control over discharge temperature. Liquor displacement efficiency is maximized. Accurate temperature control eliminates the potential for flashing on vacuum type washers. Compact and straight flow-through design also makes the Pick Heater the correct choice.

Features and Benefits:

• Precise Temperature Control

• Instantaneous Supply of Hot Water

• Automatic Operation