Application:

When a major meat processing company committed to building a waste to energy facility, it selected Pick Steam Injection Heaters. The plant addresses the growing concerns of handling and disposal of livestock waste while providing a source of clean, renewable fuel.

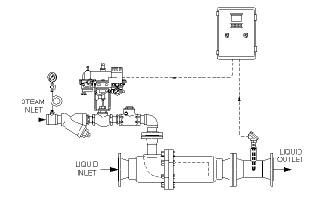

Swine manure is collected, thickened to 8% solids, then digested. Using a progressive cavity pump, sludge is drawn from concentrators at a rate of 80-100 GPM. Temperature is instantly raised from 40°F to 95°F as it is fed through a Pick Steam Injection Heater en route to the digester. Methane gas is collected from the top of the digester, converted into methanol and transported to an offsite biodiesel plant.

Solution:

Two model 6X50-3 Pick Heaters have been in service since the plant began operations.

Features and Benefits:

• Compact

• Energy Efficient

• Precise Temperature Control

• Trouble Free Operation