Application:

An automotive manufacturer was using a plate heat exchanger for a final phase spray wash to remove honey oil from transmission parts. The plate exchanger was used to superheat a slip stream of water to 224ºF, discharging to the washer reservoir, arriving at a blended temperature below 200ºF. The elevated temperature caused the residual oil to gum up the plate exchanger which required frequent cleaning.

Process Conditions:

Maximum Water Flow Rate: 50 GPM

Inlet Temperature: 135ºF

Discharge Temperature: 160ºF

Steam Supply Pressure: 75 PSIG

Water Supply Pressure: 50 PSIG

Steam Flow Required : 590 lbs./hr.

Solution:

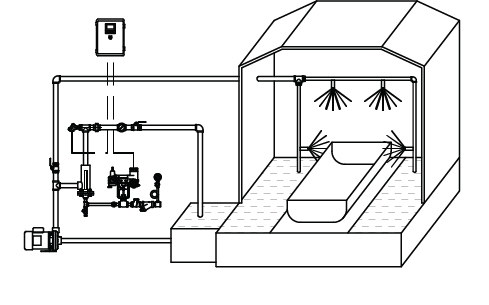

Pick Model 6X7-3 Constant Flow Heater. After the Pick Heater was installed it was determined that the process could be operated at a much lower temperature. Direct Steam Injection and the Pick “flow-through” design eliminated the gumming problem.

The Pick Heater consumes about 10% less steam than the plate exchanger, saving the customer fuel and steam. The heater also features an electronic steam valve actuator and temperature controller because no compressed air was available in that area of the plant.

Features and Benefits:

• Compact Design

• Energy Efficient

• No Plates to Foul/Plug

• Fully Automatic

• Accurate Temperature Control