Application:

An industrial uniform and apparel rental service was looking to replace a shell-and-tube heat exchanger for supplying hot water to their laundry washing machines. Nearly 40,000 gallons of hot water was required per 16 hour day to keep up with demand. Pick's representative quickly identified the potential energy savings through converting to direct steam injection heating.

Process Conditions:

Water Flow Rate: 85-105 GPM

Preheated Water Supply Temperature: 80ºF

Discharge Temperature: 155ºF

Steam Pressure: 125 PSIG

Water Pressure: 55 PSIG

Solution:

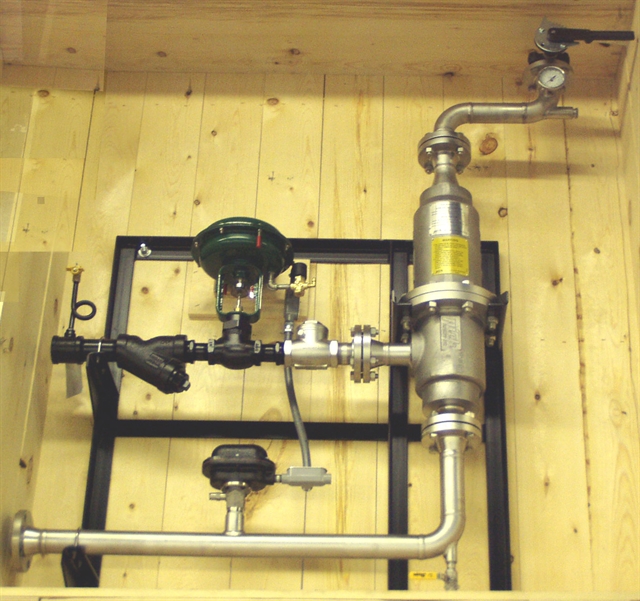

A Pick Model 6X50-3 Constant Flow Heater, 316 stainless steel flanged construction.

Through Pick's Energy Savings Comparison Program a 16% steam savings was calculated. This substantial energy and cost savings existed even after considering the added cost of treating boiler feed make-up water resulting from condensate no longer being returned to the boiler. A net savings of $7.91/hr was gained by installing the Pick Heater. The bottom line was a savings of $33,411.00.

Features and Benefits:

• Energy Efficient

• Compact Design

• Quickly Achieves Set Point

• Complete System Supply