Application:

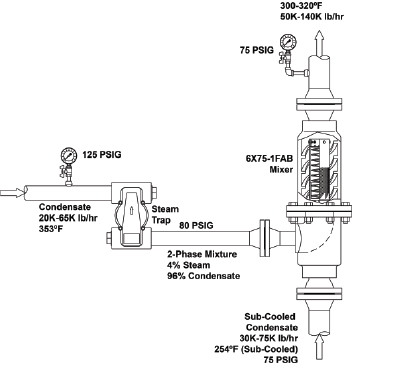

A west coast refinery was working on a project to eliminate hammer on condensate return lines off of three sour water strippers. The problem occurred as subcooled condensate collected off of two strippers mixed with flash condensate off the trap of a third stripper using a shell-and-tube kettle reboiler. As the flash steam condensed in the cooler stream, a large volume collapse occured causing instability and hammer throughout the condensate return piping system. A method was required to smoothly mix the subcooled condensate stream (254ºF/75 PSIG) with a two-phase, flash condensate flow (335ºF/80 PSIG) coming off the trap of the shell-and-tube.

Solution:

Pick Heaters Inc. custom designed a heater/mixer to fit within the existing piping scheme of the return header, allowing for horizontal installation. The natural benefits of the Pick Heater and it’s unique injection tube design provided an effective way of blending condensate streams smoothly. The Pick injection tube provided refinements over crude inline spargers: 1) finer breakup of two-phase condensate flow 2) angled directional injection promoting mixing in helical chamber, and 3) modulating piston to compensate for load changes. The result was a simple but successful solution.

Features and Benefits:

• Complete Mixing of Condensate Streams

• Eliminates Hammer