Application:

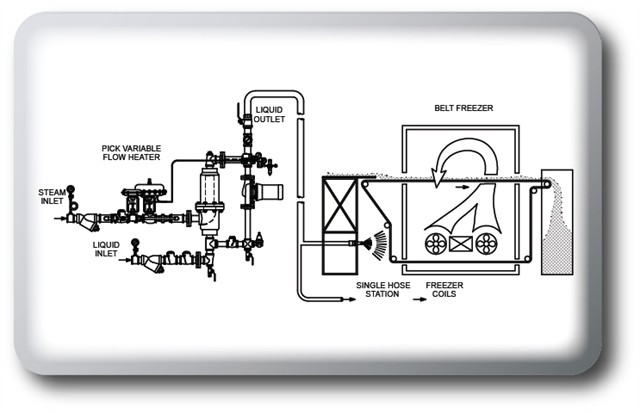

Frozen vegetable processor required a method to remove ice build-up on multiple belt freezers. The product was continuously fed on a conveyor belt through a freezer system to keep up with production demands. Ice build up on the belts must to be melted at timed intervals. Hot water was distributed onto the belts via a series of spray heads. Water demand varies based on sequencing of washing cycles and number of systems in operation. Additional hot water is used to defrost refrigeration coils and supply a nearby single hose station for plant wash down in freezer area.

Process Conditions:

Water Flow Rate: 30-250 GPM

Temperature Rise: 15°F

Final Temperature: 85°F

Steam Supply Pressure: 110 PSIG

Water Supply Pressure: 40 PSI

Steam Flow Required: 200-1600 lb/hr

Solution:

Pick 6X50 Variable Flow Heater designed with 4" water piping suitable for 250 GPM water flow rate. Dual steam valves are included to handle a wide range of steam flow demand. The Variable Flow Heater provides smooth performance in responding to intermittent operation and changes in water flow rates.

Features and Benefits:

• Instantaneous Supply of Hot Water

• Compact Design

• Turndown Capabilities

• Single Source of Hot Water for Multiple Use Points