Application:

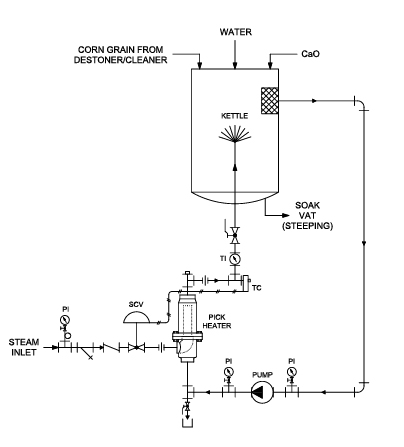

A tortilla chip manufacturer was looking for a method to speed up their batch alkali cooking process. Cleaned corn grain, 140°F water and lime solution is batched, cooked and converted to a product called "nixtamal". The nixtamal is then sent to an overnight steeping process. Corn grain was being cooked up to 200°F in a 500 gallon steam-jacketed kettle. A secondary kettle was used to keep up with production. The steam jacket, indirect heating method took up to 20 minutes to reach cook temperature. Another inherent problem was that heat was not evenly distributed within the batch, creating localized hot and cold spots, affecting product quality.

Solution:

Pick 6X50-3HWS Packaged Heating System. The customer turned to Pick Heaters, Inc. to provide a system where the contents of the batch are continuously circulated at 200gpm through a Pick Direct Steam Injection Heater, heated to 200°F, and then pumped back into the center of the kettle. The open, low velocity design of the Pick Heater handled any unscreened corn fibers or particles without plugging of equipment or degradation of product. In-line heating resulted in thorough and even heating. Tank agitation created by the pumping action also enhanced uniform cooking. Batch time was cut more than half to 8 minutes. The shortened cycle time

allowed for the elimination of a second kettle.

Features and Benefits:

• Significantly lowered batch time, increasing productivity

• Uniform cooking under precise temperature control improved product quality

• Eliminated capital cost of second vessels