Application:

Heat & cool 4,000 gallon Pfaudler® glass lined jacketed vessel. Lubricant type product is heated to 310°F using 316°F water. Exothermic process was maintained at 325°F for 3.5 hours then cooled to 210°F.

Solution:

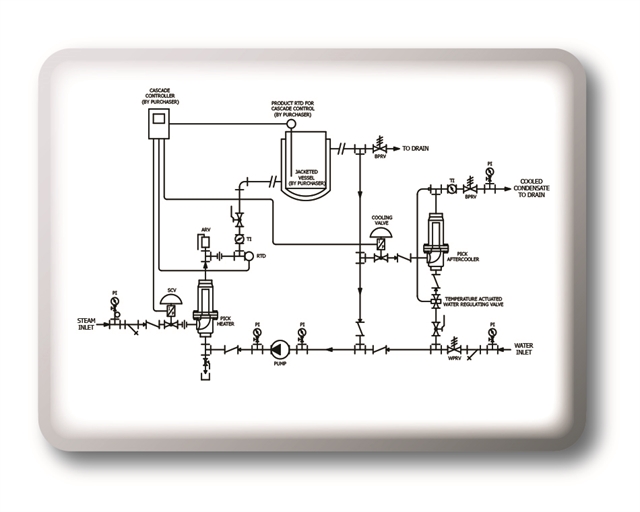

Pick Model 6X50-3/12HCAC all 316 SS.

The pressurized water loop at 80 psig allows 316°F water temperature, permitting a smooth transition from heating to cooling.

Accurate temperature control prevents damage to glass lining (+/- 1/2° accuracy).

Heat/Cool system was packaged complete with after cooler (Pick mixing chamber) for tempering of discharge cooling water (up to 320°F), blended to 150°F for return to cooling tower.

Features and Benefits:

• Accurate Temperature Control

• Fully Automatic Operation

• Compact Design

• Smooth Transition from Heat to Cool