Direct steam injection (DSI) heating is a highly efficient method of heating fluids and slurries by directly injecting steam into the process fluid. This technique ensures rapid and uniform heating, making it ideal for various industrial applications.

Direct steam injection heats water or other process fluids by injecting steam directly into the flowing fluid. As the steam condenses, all its energy, both sensible and latent heat, is transferred instantly into the fluid, raising the temperature rapidly and uniformly.

This differs from indirect heating methods, such as heat exchangers or steam coils, where heat must pass through a heat transfer surface. Indirect systems often struggle to maintain tight temperature control under changing flow or demand conditions.

With DSI, heating occurs on a continuous, straight‑through basis—there is no need to store large volumes of hot water, and heating stops immediately when demand stops.

Pick Direct Steam Injection Heating Systems can be used to heat any water-miscible fluid or aqueous slurry instantaneously where steam pressure is greater than the liquid-side pressure.

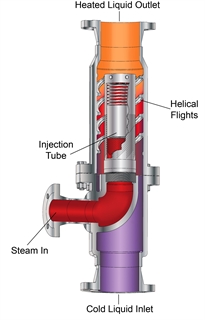

To heat the process fluids, steam is dispersed through the precisely arranged orifices in many fine streams promoting rapid mixing and instantaneous heat transfer. As the steam enters the internal injection tube, it acts against a spring-loaded piston to expose some or all the orifice pattern. As the steam input varies due to load changes, the piston modulates to adjust the number of exposed orifices providing rapid response to process changes.

The spring and piston arrangement prevents equalization of steam & liquid pressures thus eliminating harmful shock and vibration caused by steam hammer. The helical flights inside the chamber ensure complete and thorough mixing of steam and liquid.

With a Pick Heater, there are no minimum up or down-stream pipe length requirements. All steam is smoothly condensed within the mixing body. Liquid pressure drop is typically only 1 PSI, and the sound level is usually 85 dBA or less. This is an important contrast to high-velocity or venturi type DSI units.

Applications

DSI heating is widely used in industries such as food processing, chemical manufacturing, pharmaceuticals, and pulp and paper. It is particularly beneficial in applications where rapid and uniform heating is essential.

Ready to improve your process heating performance? Talk with a Pick Heaters expert to see how direct steam injection can deliver faster response, tighter temperature control, and reliable hot water on demand for your operation.

Contact us today to get started.