Direct Steam Injection (DSI) Heaters are systems that inject steam directly into a liquid or slurry to heat it up to a desired temperature. They are widely used in various industries, such as food processing, chemical, pharmaceutical, pulp and paper, or general industrial process heating. DSI heaters offer many advantages over other heating methods of heat exchange such as shell-and-tube units, but one of the most important benefits is their precise and accurate temperature control.

Precise and accurate temperature control means that the DSI heater can deliver the exact temperature required for the process, within a very narrow range of variation. This tight temperature control is possible because steam contacts the process fluid immediately at the point of injection. There is no heat transfer barrier such as plate packs or tube bundles that can foul and limit transfer of BTUs.

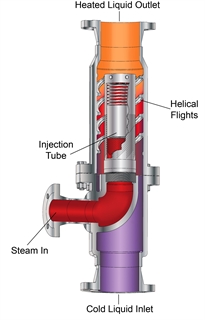

With a Pick Heater, as the steam enters the internal injection tube it acts against a spring-loaded piston to expose some or all the orifice pattern. As the steam input varies due to load changes the piston modulates to adjust the number of exposed orifices providing rapid response to process changes.

The benefits of precise and accurate temperature control with DSI heaters are many:

Precise and accurate temperature control is a key feature of DSI heaters that makes them superior to other heating methods. If you are looking for a reliable, efficient, and cost-effective heating solution for your industrial process, you should consider using DSI heaters from a reputable manufacturer like Pick Heaters. We have decades of experience and expertise in designing and installing DSI heaters for various applications and industries.

Contact us today to find out how we can help you achieve your heating goals.