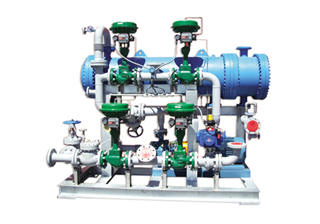

A Pick BX Steam Injection Heater offers precise heating of starch and water-miscible slurries. It’s a great choice for viscous slurries like waste grease, FOG sludge or oil extraction.

Application- Organic Wastewater

- Slurry Cooking

Industry- Chemical

- Energy & Power

- Ethanol & BioFuel

- Food & Beverage

- Pharmaceutical

- Pulp & Paper