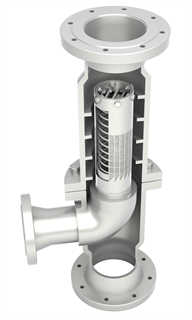

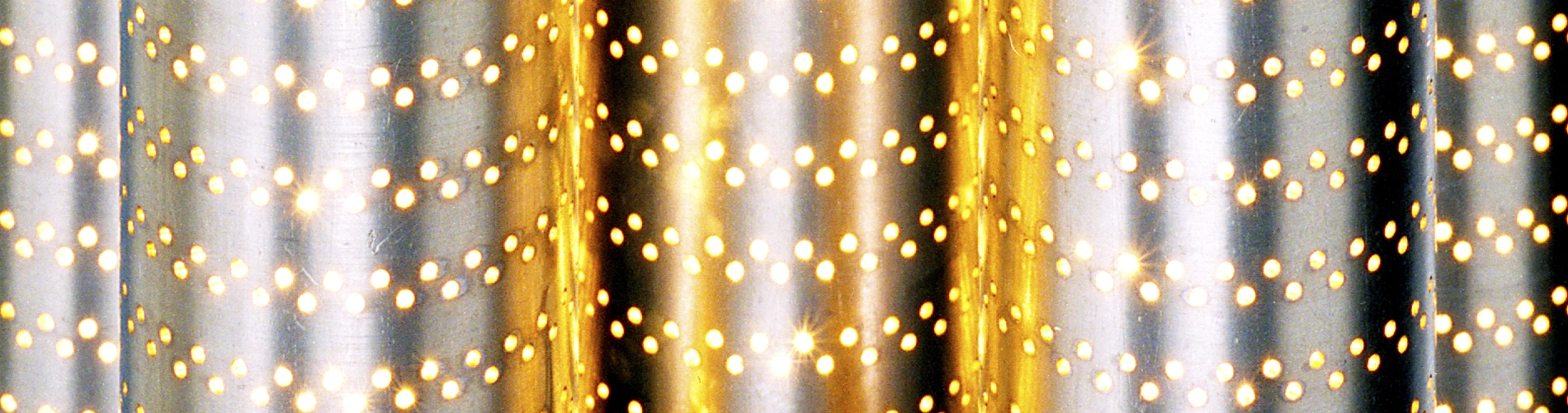

To heat liquids, steam is dispersed through the precisely arranged orifices in many fine streams promoting rapid mixing and instantaneous heat transfer. As the steam enters the internal injection tube it acts against a spring-loaded piston to expose some or all the orifice pattern. As the steam input varies due to load changes the piston modulates to adjust the number of exposed orifices providing rapid response to process changes.

The spring and piston arrangement prevents equalization of steam & liquid pressures thus eliminating harmful shock and vibration caused by steam hammer. The helical flights inside the chamber ensure complete and thorough mixing of steam and liquid.

With a Pick Heater, there are no minimum up or down-stream pipe lengths, liquid pressure drop is typically only 1 PSI, and the sound level is usually 85 dBA or less.