The natural benefits of the Pick Heater and its unique injection tube design provide an effective way of blending condensate streams smoothly.

Formation of two phase flow on discharge side of steam traps creates pockets of flash steam that can collapse and cause damaging vibration and steam hammer in the return header. The problem is most severe when mixing condensate streams with wide variance in pressure and temperature. An example of this is discharge of high temperature condensate into a header containing sub-cooled condensate at lower pressure – a common situation at refineries and related industries.

Application Data Forms & Brochure Downloads

Need a quote for a Pick Steam Injection Heater? Save time by submitting an application data sheet. Just looking for additional information on our products? Download our product specific brochures.

Need a Replacement Part or Manual?

Request Replacement Parts

Contact us to order the parts you need to keep your Pick Heater up and running.

Request a Manual

Contact us to request a copy of the Service and Installation Manual for your Pick Heater.

Industries Include:

Have a Question or Need More Information?

We’re committed to providing the best customer support before and after the sale with a team of factory sales engineers that are recognized experts in the industry. They’re ready to put that expertise to work for you.

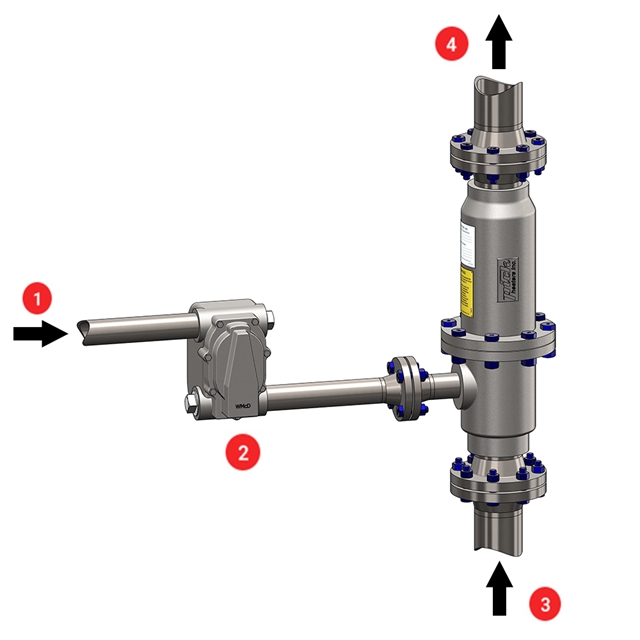

Eliminates steam hammer and pipe damage when mixing condensate streams at different pressure and temperature. High temperature condensate forms a two-phase mixture with drop in pressure as it is discharged from the trap. This stream is dispersed through numerous small orifices into sub-cooled condensate, flowing through the main housing of the mixer. This promotes immediate absorption, thus preventing formation and collapse of large steam bubbles to eliminate hammer.

A Pick Heater provides an effective method of condensate mixing. Sub-cooled condensate flows unobstructed through the main housing. Discharge from the high pressure trap is dispersed into the sub-cooled condensate through the multiple orifice injection tube. This breaks the two phase flow into fine streams to promote immediate condensation of flash steam, thus eliminating vibration and steam hammer. Pressure and temperature balance are such that flash steam is fully condensed, resulting in discharge of 100% liquid at outlet of the mixer.