Profile of Pick Heaters, originators of Direct Steam Injection Heaters.

Our History

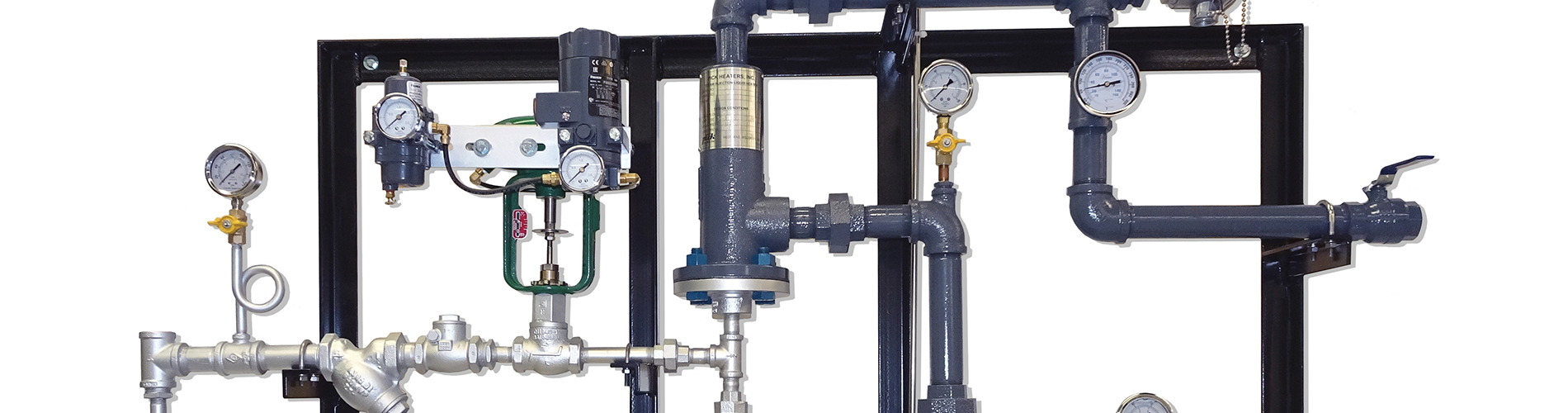

In 1945, Pick Heaters developed and patented a unique concept of Direct Steam Injection Heating. It was the first step in what was to become a continuous flow of refinement and innovation. It is this design philosophy that has Pick at the heart of heating for over 80 years in industries ranging from food to chemical and pharmaceutical processing, pulp and paper, textile to power plants.

Out of this philosophy has come a continuous flow of refinements and innovations.

Energy Efficient

100% heat transfer cuts fuel costs up to 28%

Precise Temperature Control

To within 1°C or less for many systems

Wide Operating Range

Variable orifice injector provides unlimited turndown

Low Noise Level

Normally below 85 dBA

Low Liquid Pressure Drop

Does not exceed 2 PSI under design flow rates

Complete Mixing in Heater Body

No need for straight run pipe lengths after heater

Pick Heaters has a worldwide network of qualified engineers along with its highly qualified factory staff to work with you to design a process heating system to meet your specific requirements. Pick's international certifications include: CRN/Canada and CE/Europe.

Pick combines the Right Products with the Right People - Pick the Best.

For more information - contact us.