Food processing plants face many challenges in ensuring the safety and quality of their products, as well as complying with strict regulations and standards. One of the key aspects of the food industry is process heating, which is required for various purposes such as cooking, pasteurization, sterilization, and cleaning. Heating must be done efficiently, with accurate temperature control to avoid product spoilage, contamination, or waste.

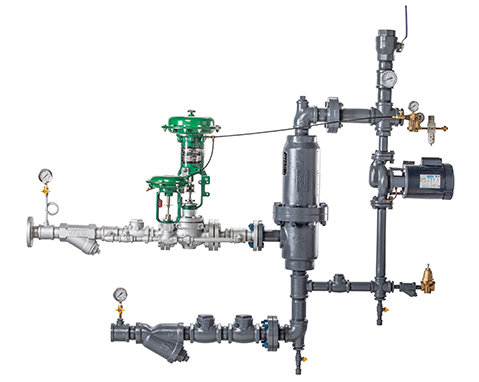

One of the most effective and reliable methods of heating liquids and slurries in food processing plants is direct steam injection (DSI) heating. DSI heaters are inline heaters that inject steam directly into the liquid or slurry. The steam bubbles transfer heat energy to the fluid, resulting in rapid and uniform heating. DSI heaters can handle a wide range of viscosities and solid contents and can achieve precise temperature control.

DSI heaters are widely used in various food processing applications, such as:

Cooking: DSI heaters can cook soups, sauces, gravies, starch slurries, concentrates, and other products with high viscosity or solids content.

Pasteurization: DSI heaters can pasteurize milk, cream, yogurt, cheese, juice, beer, wine, and other beverages. Bottle and can pasteurizing also require a dependable supply of hot water.

Sterilization: DSI heaters provide hot water for clean-in-place (CIP), sanitizers, and other fluids used for cleaning and disinfecting equipment and surfaces.

Cleaning: DSI heaters can heat water for washing or rinsing machinery or equipment, controlled at optimum temperatures for efficient use of caustic soda or other chemical additives.

DSI heaters offer many benefits for food processing plants, such as:

Energy efficiency: DSI heaters use 100% of the steam’s energy for heating, resulting in up to 28% energy savings compared to indirect heat exchangers.

Product quality: DSI heaters provide instant and consistent heating of food products at precise cooking temperatures. DSI heaters also prevent degradation of the product.

Plant safety: DSI heaters can provide a safe and reliable hot water supply for plant washdown, eliminating the steam source at point of use, minimizing the risk to personnel.

Space saving: DSI heaters are compact and easy to install within existing piping systems, requiring less floor space or complex piping arrangements.

DSI heaters are a proven technology that can enhance food processing plant safety and efficiency by providing efficient, accurate, and hygienic heating solutions. By choosing DSI heaters from reputable manufacturers such as Pick Heaters, food processing plants can improve their product quality, reduce their energy costs, and comply with their regulatory requirements.

Need a quote for a Pick Steam Injection Heater? Save time by submitting an application data sheet. Just looking for additional information on our products? Contact us to get in touch with your local representative.